compressed sawdust pallet production line| molded wood pallet making equipment

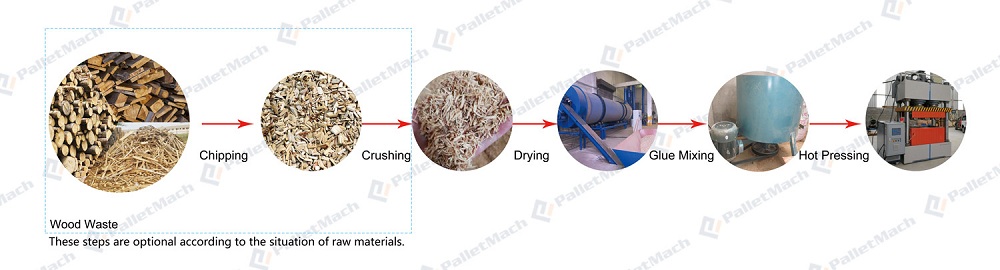

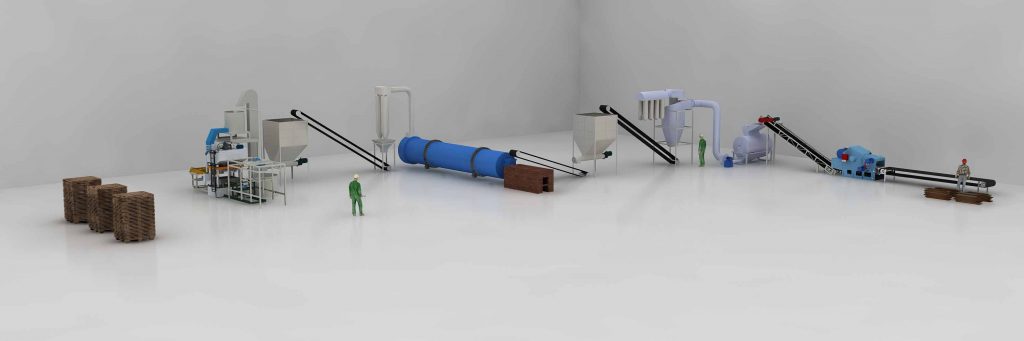

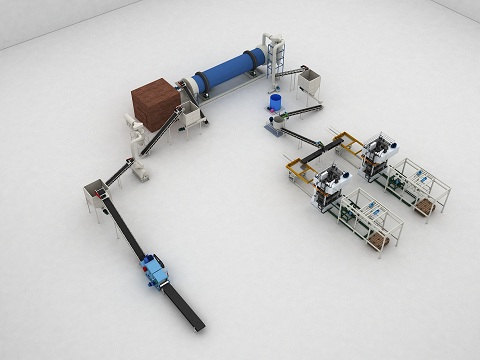

The compressed wood pallet production line is a set of pallet forming equipment independently developed by our company. Compressed wood pallet production line equipment is mainly used to produce sawdust wood pallets. Our company mainly produces Presswood pallet machine equipment. The raw materials are different, and the processing technology is also different. The waste wood, wood chips, and wood shavings are usually used as raw materials, dried by a drum dryer, and mixed with glue, and then heat-pressed to make the compressed wood pallet at one time. If large pieces of wood are used as raw materials, wood chippers and wood crushing machines are also required to crush the wood. The compressed wood pallet production line has been proven by our factory for many years, with good stability, high production efficiency, low energy consumption, and easy installation. At the same time, each machine on the production line is designed reasonably and is very easy to operate.

introduction of compressed wood pallet production line

The quality of the wooden pallet hydraulic press production line is very important to the quality of the wood pallet produced. In the processing of pressed wood pallets, processes such as drying, glue mixing, and molding are required, and each process needs to be strictly controlled. The automatic hot press thermoforming wood pallet production line equipment mainly includes a wood chipper, wood crusher machine, drum dryer, glue mixing machine, compressed wood pallet machine. The mold of the molded wooden pallet machine can be customized according to the shape and size of the pallet you want to produce. Customers can choose the machine according to the demand for production capacity. The sawdust Presswood pallet produced by our company’s compressed wood pallet machine has a solid structure with good waterproofness (no cracking in water for 48 hours, no cracking in wind and sun).

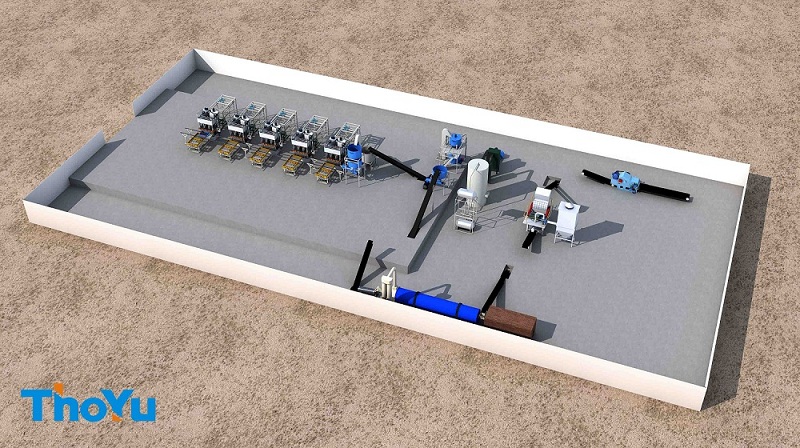

Automatic wooden moulded pallet production line with different capacities and station

Wood chipper machine in compressed wood pallet production line

The wood chipper can crush all kinds of logs, boards, bamboo, branches, trunks, wood, etc. into wood chips. Wood chipper machine is usually divided into disc chipper machine and drum chipper machine, The size, and length of wood chips can be adjusted according to the needs of users. Wood chipper equipment is widely used in paper mills, fiberboard mills, particleboard mills, and wood chip production bases. It is the ideal wood chip processing equipment for many customers. When the wood chipper machine is used in the hydraulic pallet press production line, it usually cuts large wooden boards into small pieces.

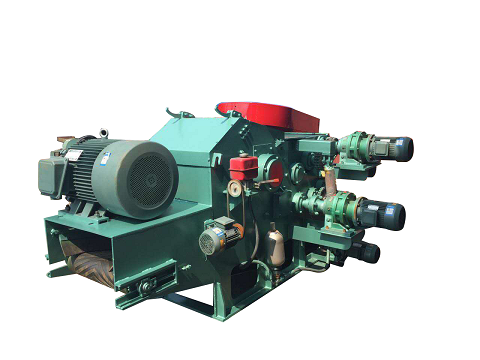

wood crushing machine in compressed wood pallet production line

Wood crushing machine is a crushing equipment specially designed for wood press pallet production line and wooden block production line by our company according to market demand. It can mainly crush waste wood, wooden pallets, bark, and woodblocks that have been chipped by a wood chipper. The sawdust grinder mainly includes the main engine, motor (diesel engine), fan, dust removal equipment, power distribution cabinet, etc. When the wood crusher is working, the material enters the crushing chamber through the feed port. The blade of the crushing chamber is driven by the rotating shaft to cut the material, and when the material is crushed to the appropriate fineness, it is drawn out from the screen.

Drum dryer for wood pallet

The wood processed by the wood chipper and wood shredder contains a lot of moisture, and it will affect the quality if it is processed directly into wooden press pallets. Need to remove moisture before processing into wooden pallet. Sawdust dryer is an equipment specially designed and manufactured by our company for the drying of sawdust, wood chips and other materials. It has the characteristics of large drying output, significant energy-saving effect, and low maintenance.

Glue Mixer for wood press block production line

The mixing of shavings and fibers with glue in the production of molded pallets is called the glue mixing process. The glue mixing machine is important equipment to realize this process. The mixing of shavings or fiber and glue is a complicated process, which directly determines the strength of the produced pallet. The amount of glue mixed or the ratio of glue in sawdust will directly affect the strength and production cost of wood-based pallets.

The working process of the glue mixing machine

The sawdust enters the barrel of the glue mixer, and the knife blade drives the raw material to rotate and turn along the inner wall of the barrel. While rotating, pour in the glue that has been proportioned. The materials circulate continuously in the tank and stir each other. Through such high-speed rotation, it can be quickly mixed evenly.

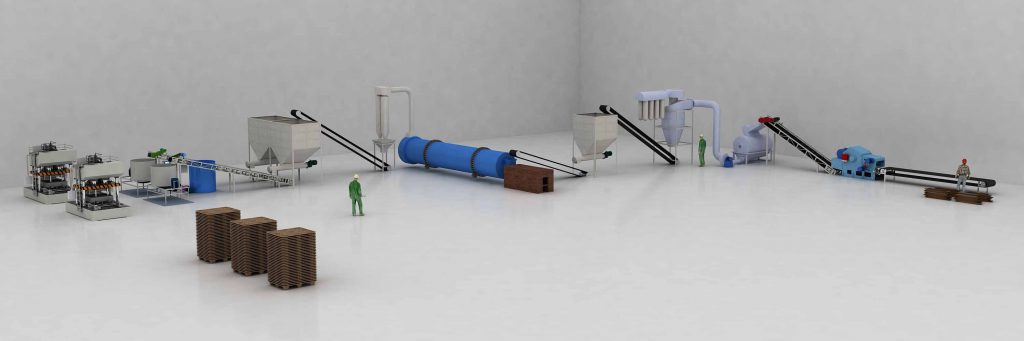

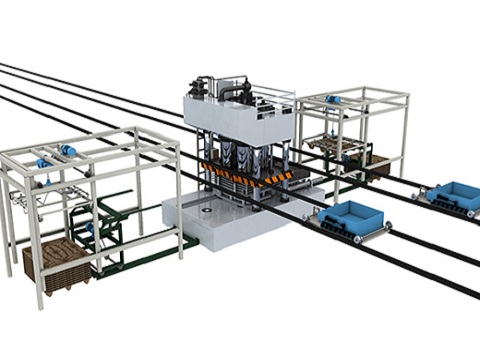

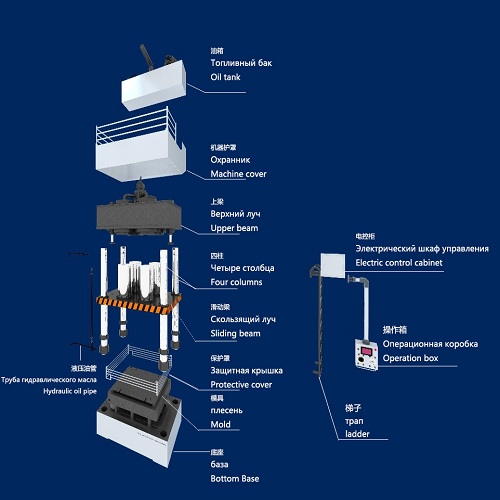

sawdust pallet press making machine

The molding wood pallet machine is the core equipment of the molding sawdust pallet production line. It has a wide range of sources of raw materials. The raw materials can be wood chips, straw, sawdust, etc., and various waste wood materials can also be used to process pallets. The equipment has an independent hydraulic system, The equipment has an independent hydraulic system, which can provide sufficient pressure, and the pallet can be molded at one time. During processing, the material is laid flat in the mold of the wooden pallet molding machine. The molding machine can automatically complete the whole process of pressing, pressing, holding pressure, timing, pressure relief, demoulding, and lifting.

The mold of hydraulic pallet press machine

The mold is the main part of the wooden pallet forming machine, which is divided into two parts, an upper convex mold, and a lower concave mold. When the mold is closed, the raw material can be molded under high temperature and high pressure, and when the mold is separated, the molded wood pallet can be taken out. The production of different pallets requires different molds. According to the different requirements of molded pallets, molds are also divided into multiple styles, multiple specifications, and multiple sizes. Our company can produce suitable molds according to customer needs.

Advantages of wood press pallet production line

- The raw materials can use various waste wood materials, which improves the utilization rate of wood.

2. The pallets produced by the wooden pallet molding machine are cheaper than other wooden pallets, and there are no nails on the pallets, which will not scratch the goods.

3. Sawdust molded pallets can be fed in four directions, which can meet the needs of various forklifts. The pallet has a large carrying capacity, with a static load of 3 tons and a dynamic load of 1.5 tons.

4. The production line runs stably, the production efficiency is high, and the energy consumption is relatively low. It is a good investment project.

Our clients

Our products are of high quality, and the machines we produce are sold all over the world, and we have a group of long-term customers. Our company has 20 years of production experience in the pallet machinery industry, and the machinery produced is unanimously praised by customers. If you have any investment in this area, please contact us.