waste wood crushing machine | wood crusher machine price

The wood crushing machine for pallet is mainly used to process pinewood, miscellaneous wood, poplar wood, fir, raw bamboo, and waste wood materials. It is an important step in the production of molded press wood pallets and pallet blocks. The wood crushing machine for pallet is the special equipment for wood crushing designed by our company according to the needs of producing wooden pallets. This machine has a reasonable design, compact structure, and high production efficiency. You can use our wood crusher machine to process common wood in daily life, all kinds of branches, slats, slats, small diameter round core wood, scraps, wood chips, Moso bamboo, cotton stalks, and other materials can be processed into sawdust and wood filament products at one time, with low investment, low energy consumption, and high productivity, Good economic efficiency, etc.

Introduction of wood crushing machine for pallet

Wood crusher machine for pallet is a new type of woodworking machinery and equipment for producing sawdust. It can process wood, tree branches, and other raw materials into sawdust at one time. This machine has the advantages of low investment, low energy consumption, high production efficiency, good economic benefits, and convenient use and maintenance. A wood crushing machine is a series of special equipment for wood shredding that our company invented after years of research according to the needs of industrial production. The wood chips produced by our company are compact in structure, safe and durable, and have high production efficiency. After being promoted and used, it has been widely praised by customers.

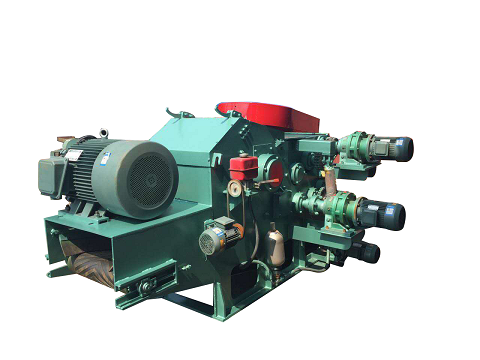

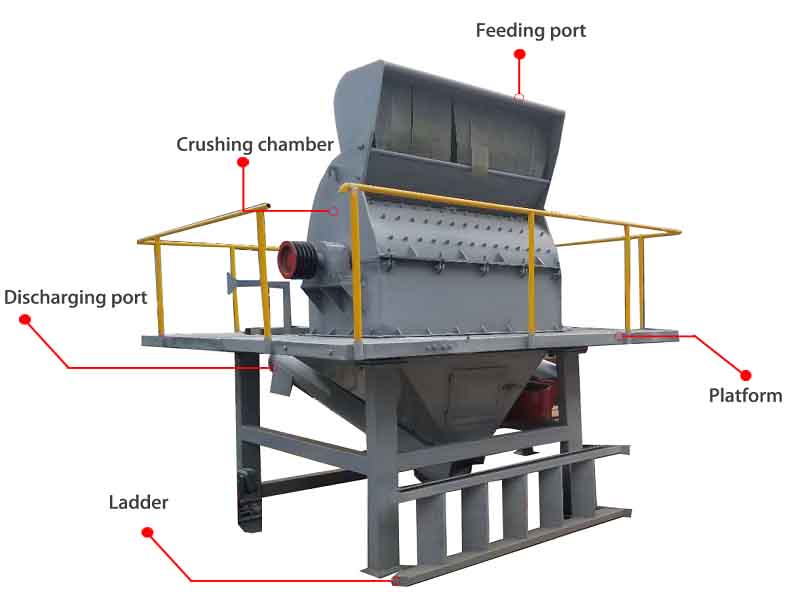

Structural characteristics of wood crusher machine

The wood crushing machine for pallet is mainly composed of a casing, a bearing, a screen, a transmission wheel, and a trough steel frame. All materials are cast from manganese steel. The overall structure of the wood shredder is composed of three parts: feeding mechanism, crushing chamber (rotor, hammer, screen, tooth plate), and discharging part (fan, collecting barrel, dust bag). When working, the material enters the crushing chamber from the feeding mechanism and flies to the tooth plate under the impact of the high-speed rotating hammer. After the material collides with the tooth plate, the material rebounds and is hit by the hammer again, and at the same time, the material is subjected to strong friction between the screen surface and the hammer. Under repeated impact, collision, and friction, the material is gradually crushed and then discharged after being screened by a screen.

Application fields of wood crusher for pallet

A lot of waste wood can be produced in our wood crusher for pallet, Waste wood can be reused, and the use of waste wood after being processed and crushed by a wood crusher machine can be beneficial to reduce wood waste, and it has a great effect on the green environment. The wood shredder also can be used in the foot block production line and the molded wood chip pallet production line. In the production process, large pieces of wood chips cannot be used directly, and need to be crushed into granules to facilitate subsequent drying and glue mixing.

The working principle of waste wood crushing machine

The wood crushing machine utilizes the relative movement of the six internal high-speed movable hammers and the surrounding fixed gear ring to make the materials collide and rub against each other by the hammer teeth to be crushed. The crushed materials are filtered by the sieve and flow out after being subjected to the rotating centrifugal force. The wood crusher uses the impact crushing method to crush materials. The motor drives the rotor of the crusher to run at a high speed. When the rotor rotates, it produces a high-strength impact and cutting force on the crushed materials, and achieves the crushing effect. When in use, test the machine with no load for 1-2 minutes, and wait until there is no abnormal phenomenon before putting in the material. When putting in materials, the material flow must be increased evenly and gradually. Observe the operating conditions of the machine when it is working, and stop feeding before shutting down.

Parameters of high-efficiency wood crusher machine

| model | TY-1500 |

| Main motor power (kW) | 2P-55kw×2 |

| Capacity (t/h) | 5-8 |

| Number of blades (pieces) | 66 |

| Grinding size (mm) | 3-30 |

| Discharge screw power (kW) | 4P-7.5kw |

| Dimensions (m) | 3.15×3.25×3.35 |

| Weight(t) | 5.5 |

| Speed (r/min) | 2400 |

How to use wood crusher

First, put the wood crusher in a proper position, place it steadily, and then turn on the power and start the test machine after the machine is running. Before use, it is necessary to check whether the transmission part of the machine is loose and the rotation direction of the machine should be consistent with the direction shown by the arrow.

After purchasing the machine, our company will give you an installation and operation manual and will provide you with professional technical guidance. If you have any needs, you can contact us in time.