plastic recycling extruder|Plastic extrude machine

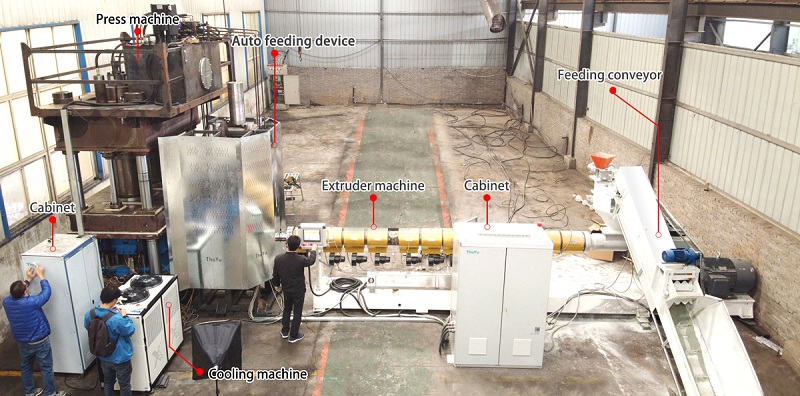

The plastic extruder for pallets is common plastic machinery, which is widely used in the plastics processing industry. Plastic extruders can be divided into single-screw extruders, twin-screw extruders, and multi-screw extruders according to the number of screws. At present, the single screw extruder is the most widely used, suitable for the extrusion processing of general materials. Plastic extruders are usually used in plastic molding production lines to process waste plastics into various products. We are a professional manufacturer of plastic pallet machinery, and the Single screw plastic extruder we produce usually be used in the plastic pallet production line. The recycled plastic is heated by an electric heating tube and extruded and sheared by a single screw in a plastic extruder to become a melt, and then formed in a plastic pallet press molding machine.

Introduction of plastic extruder for pallet

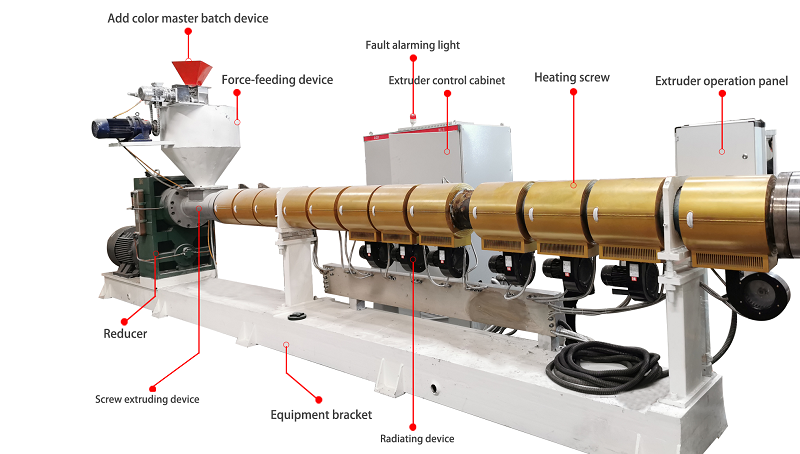

A plastic extruder is a kind of plastic equipment that melts and extrudes plastic. The material is continuously extruded through heating and extrusion, which has the advantages of high efficiency and low cost. It is the necessary equipment in the production line for producing molded plastic pallets. This plastic extruder is a single screw plastic extruder, which is equipped with a feeding system, lubrication system, extrusion system, heating system, and automatic control system. Most of the parts and electrical components adopt well-known foreign brands such as NSK, ABB, Schneider, etc., which have the characteristics of stable operation, high efficiency, and easy maintenance.

Structure of plastic extrusion machine

The plastic extruder processes the waste block plastic into a melt. It is composed of an extrusion system, transmission system, and heating system.

Extrusion system

The extrusion system includes a screw, barrel, and hopper. The plastic is formed into a uniform melt through the extrusion system and moves forward under the push of the screw.

Transmission system

The transmission system is mainly composed of a motor, reducer, supply screw, and drive screw. The torque and speed required in the extrusion process are usually provided by an electric motor.

Heating system

The plastic extruder usually uses electric heating, and the heating tube is installed in the body. The heating device externally heats the plastic in the cylinder to heat it up to reach the temperature required for the process operation.

Working principle of plastic extruder

The plastic in the plastic extruder is melted under the heating of the electric heating tube, and under the pressure and shear of the screw, the solid plastic is transformed into a uniform melt. The raw materials enter the inside of the machine through the hopper above the machine. There is a feeding screw in the hopper, which can uniformly transport the material into the machine. The feeding speed can be controlled by controlling the speed of the decelerating motor above the machine. The body of this machine is mainly composed of a barrel and a screw. The barrel and the screw cooperate to crush, soften, melt, plasticize and exhaust the plastic, and continuously convey the molten plastic to the molding system of the plastic pallet-making machine.

Features of plastic extrusion machine

- Plastic extruder has high output, low energy consumption, and low manufacturing cost. The plastic extruder has high output, low energy consumption, and low manufacturing cost, and can be used for processing various plastic materials. It has applications in various industries and is usually used in the plastic product processing industry.

2. Plastic extruder has the advantages of high processing efficiency, good product quality, and safe operation. When the machine is working, there is less heat generated by friction, the shearing of the material is more uniform, the conveying capacity of the screw is larger, the extrusion volume is relatively stable, the material stays in the barrel for a long time, and the mixing is uniform.

3. The process parameters of the entire extrusion process, such as melt pressure and temperature, body temperature, and screw speed, can all be controlled by the PLC control system.

Parameters of plastic extruder

| Aspect ratio | 33:1 |

| Screw diameter | 180 mm |

| Screw speed | 75 rpm |

| Length of cylinder | 5940 mm |

| Screw center height | 1230 mm |

| main motor power | 110kw |

What we can help you

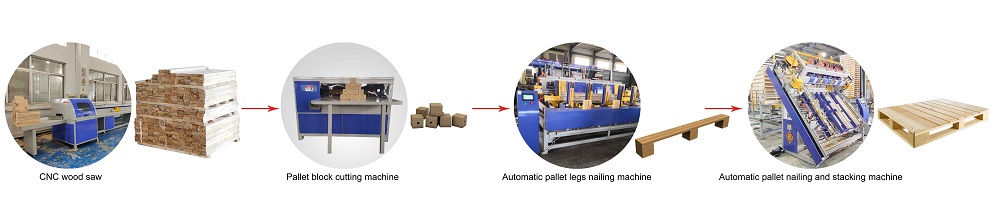

We are a professional manufacturer of plastic pallet production lines and can provide you with plastic recycling solutions. We can provide you with technical guidance based on the plastic you want to recycle. Different plastic pallets have different requirements for plastic extruders. If you have the idea of recycling plastic to produce plastic pallets, please contact us. At the same time, we also provide wood pallet machinery, sawdust molded pallet machinery, wood pallet block machine, wood pallet block production line, we can provide you with one-stop pallet production technical guidance.