Wood Pallet production line |Making American Wood Pallet

Among the pallets made of various materials, wooden pallets are the most widely used in the logistics and transportation industry. The reason is that wood pallets are light in weight, low in price, easy to make, easy to maintain, and can be recycled and reused. So wood pallet production line to produce the wood pallet is very important to the logistics industry. At the same time, the wooden pallets produced by the wood pallet production line are not easy to slip and damage the goods. The wooden structure is relatively hard and is an ideal material for making wooden pallets. Wooden pallets are made from all kinds of wood through the wood pallet production line. It is currently the most widely used in various industries. Pallets are horizontal platform equipment used for loading, handling, and transporting goods. Usually made of wood and fiberboard. Lightweight, easy to load and unload, environmental protection, and energy-saving.Today I’m going to show you how to make American pallets. And the machines needed for processing the wood pallet production line.

The structure of wooden pallets

Wooden pallets generally consist of loading surfaces, forklift holes, and hanging trough wings. The planks laid on the upper and lower sides of the pallet are called planks, and the planks need to be cut with a CNC cutting saw, and the planks on both sides are called side planks. The fork holes on the pallet are formed by stringers or spacers. The stringer is a long flat square material, perpendicular to the plank. The backing board is a square plank, and the plank on it perpendicular to the plank is called the stringer plank. The wood used for wooden pallet processing must be of high quality. Only high-quality wood can play a better role. Under normal circumstances, solid wood is selected to ensure the overall strength and structural stability through processing.

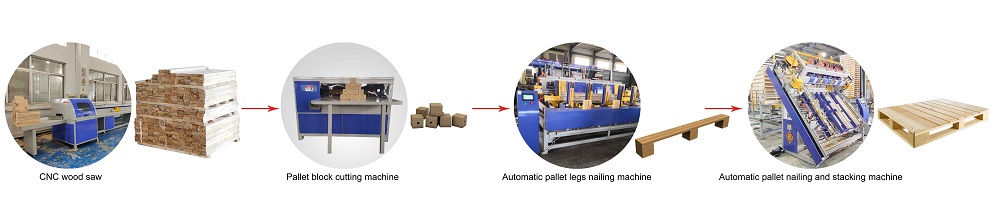

Processing process of wooden pallets

The processing process of wooden pallets is not complicated, it is made of natural wood that can be customized according to customer needs.

Selection of wood for producing wooden pallets

Material quality is an important factor affecting the processing quality of wooden pallets. Therefore, to better ensure the quality of the wood, it is necessary to choose good wood. At present, the raw materials of wooden pallets mainly include plywood, pine, Chinese fir (metasequoia), fir, poplar, and other hardwoods. In fact, different materials represent the different performance and functions of wooden pallets. The general food industry has strict requirements on the selection of pallets, and it needs to be processed with high-quality wooden boards.

Cutting wood with CNC saw

,The wood CNC saw is a wood cutting saw controlled by a computer program. It is mainly used for the cutting process of wooden pallets. In the wood cutting process, we usually use CNC saws for cutting. Compared with traditional saws, it can ensure the cutting length and thickness evenly. Our company’s wood CNC cutting saw has the advantages of standardized production, full use of raw materials, saving operators, improving production efficiency, and ensuring product safety. Therefore, CNC woodworking cutting saws can help you save production costs.

Wooden pallet stringer slotting machine slotting

The wooden pallet slotting machine performs longitudinal slotting on the pallet planks, which is mainly used to produce American-style wooden pallets. It is a special process for producing American wooden pallets. According to its processing principle, the slotting machine is divided into a single slotting machine and a double slotting machine. The double slotting machine can simultaneously make slots of the same size on a wooden board. The slotted grooves have a smooth surface, no barbs, and the quality of the equipment. Good, high operating efficiency.

wooden pallet chamfering machine

The wooden pallet chamfering machine is used to chamfer the small edges of the bottom longitudinal beams of the wooden pallet. It is a special process before the pallet is assembled. damage. The wooden pallet chamfering machine is used to chamfer the small edge of the bottom longitudinal beam of the wooden pallet. It is a special process before the pallet is assembled. It can make the forklift fork hold the pallet loosely and prevent the pallet from being damaged due to the operation of the forklift.

American pallet nailing machine nailing

American pallet nailing machine is an efficient pallet production equipment specially designed for the production of American standard pallets. This machine adopts a fully automatic program, the operating system adopts imported PLC control, the touch screen is simple to operate, the control is convenient, and the nail position is accurate. Compared with the domestic conventional production technology, the nailing machine can complete multiple procedures at one time, which greatly improves work efficiency. The American pallet nailing machine is equipped with turning, corner-cutting, hot stamping, picking, and palletizing devices. It has a high degree of automation and a stable and compact process. It can be one-stop nailing and palletizing production.

Advantages of wooden pallets in application

Based on the above introduction, I believe everyone has a certain understanding of wooden pallets. Nowadays, wooden pallets are the most widely used pallets in the logistics industry, and they play an important role in the transportation, distribution, storage, and loading and unloading of goods. Since this product has such a huge effect, what advantages does it have?

1: Among all the pallets, wooden pallets have excellent performance and can be reused.

2: The specifications of wooden pallets can be customized, no molds are needed, materials are easy to obtain, and the cost is reduced.

3: Beautiful appearance, pay special attention to the smoothness of the appearance in the process of processing, and remove burrs and burrs.

4: It has a strong bearing capacity and is firm and practical. According to long-term practical applications, wooden pallets can carry a large load.

5: It is also relatively advantageous in terms of price, which can save costs.

Matters needing attention in the production of wooden pallets

In terms of material selection. Wooden pallets are made of wood. At present, the materials of wooden pallets are mainly pine, hemlock, fir, and other miscellaneous hardwoods. In the process of selecting materials, pay attention to the quality of the wood.

The high moisture content of the wood pallet will cause the pallet to shrink and deform, or even crack. Before processing the wood, the wood needs to be dried to remove moisture.

Wooden pallets need to be strictly controlled during the production process and made according to production requirements. Each process must be inspected after processing to remove unqualified products.

How to choose a pallet machinery manufacturer

Wooden pallets are the most widely used pallets today because they are cheap and strong. Moreover, it has high accuracy and is not easy to deform. It is reinforced with high-strength screws, will not be nailed, and has good firmness. It is the best choice for many storages. Our company is a manufacturer specializing in the production of wooden pallet machinery, providing the most reasonable plan according to customer needs. The machinery produced is exported to more than 50 countries, and we have a professional technical department to provide installation services and after-sales services. Product quality has been recognized by customers in various countries. If you are interested in the process of producing pallets and how to choose a machine, please feel free to contact us.