plastic pallet press production line|plastic pallet molding production line

The plastic pallet production line mainly uses plastic or composite materials to produce plastic pallets. Our company is a manufacturer specializing in the production of plastic pallets and can provide you with suitable solutions according to different raw materials. Plastic pallets are widely used and have applications in various industries. They have high market demand and are a good investment project. Our company has a professional R&D center to continuously improve the machine. The plastic pallet press production line uses PP, PA, PE, ABS, and various waste plastics as raw materials. The price is relatively low, and at the same time, it is easy to obtain and environmentally friendly.

plastic pallet press production line manufacturer and supplier

Our company mainly produces plastic pallet production equipment. Not only will provide you with high-quality equipment, but also provide you with the corresponding production process and technical guidance. If you want to choose a reliable plastic pallet manufacturer, please contact us in time. The plastic pallets produced by our plastic pallet molding production line have the advantages of corrosion resistance, acid and alkali resistance, aging resistance, and long service life. This plastic pallet can be applied to food, medicine, chemical, textile, and other industries as logistics transportation, and industrial warehousing. Our company will provide you with pre-sales and after-sales services such as installation and commissioning, maintenance, training, and technical consultation.

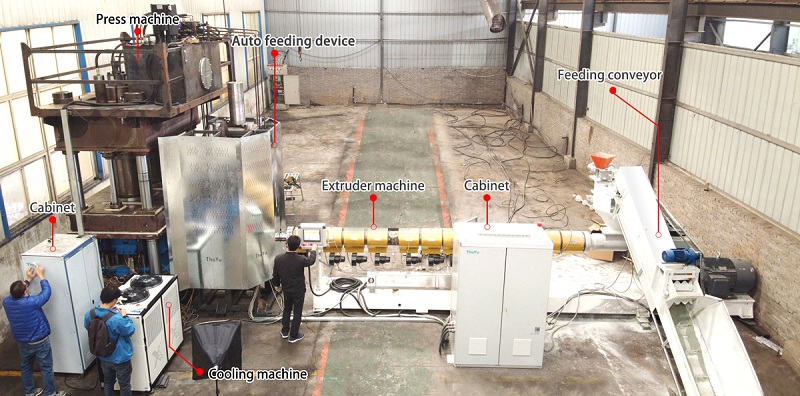

The introduction of our plastic pallet molding production line

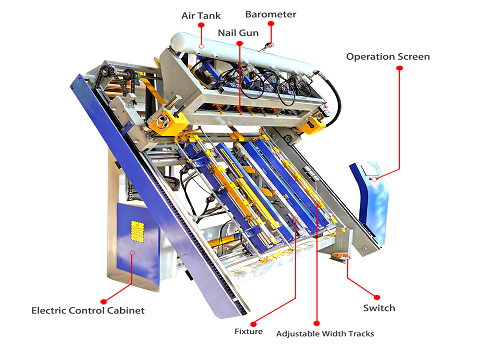

Our plastic pallet press machine is mainly composed of feeding and conveying devices, processing machinery, and control equipment. The feeding and conveying devices mainly include conveyor belts, bucket elevators, etc., which transport materials to the inside of the machine. The control system mainly includes an electric control cabinet and a sensing device, which is mainly used to control the speed and temperature of the machine. Processing equipment mainly includes plastic extruders and plastic pallet molding equipment. The plastic extruder melts the solid plastic into a melt by extruding and heating the raw material. Then, a plastic pallet molding machine presses the melted plastic into a pallet. When the plastic pallet compression molding machine is working, a water cooler is needed to cool the mold of the machine to facilitate the molding of the plastic pallet.

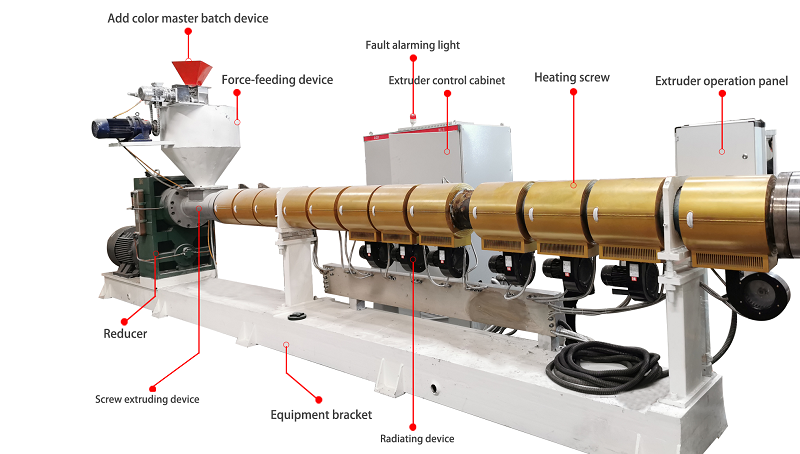

Plastic extruder in plastic pallet press production line

The plastic extruder is essential equipment in the plastic pallet press production line. The plastic extruders produced by our company are mainly single-screw extruders. The single-screw extruder relies on the pressure and shear force generated by the rotation of the screw, which can make the plastic material fully plasticized and uniformly mixed. There is an electric heating tube outside the barrel of the extruder, which can heat the plastic while the screw is extruding.

Composition of plastic extruder

The single-screw plastic extruder mainly consists of six parts: transmission part, feeding device, heating part, barrel, screw, and hopper. The transmission part is usually composed of a motor, a reduction box, and a bearing, etc. The feeding device includes a hopper and a lifting and conveying device, which mainly adds materials to the machine for processing. The screw rotates in the body of the plastic extruder to cut the extruded material, and there is a layer of the heating tube on the outside of the machine.

plastic extruder cost and plastic extruder machine price

Our company is a professional manufacturer of plastic pallets and has accumulated many years of technology. The plastic extruder produced has high output, low energy consumption, and low manufacturing cost. The price of plastic extruders is lower than other factories, but the quality is guaranteed. At the same time, we have improved the production process, saving electricity and labor costs when processing the plastic extruder, saving you money.

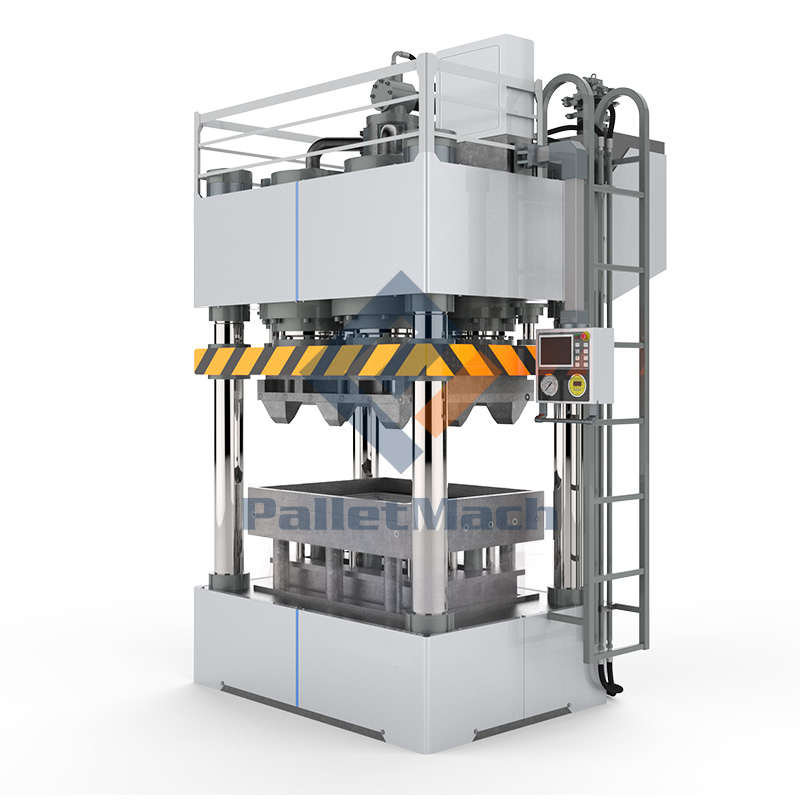

plastic pallet press molding machine in production line

The plastic pallet press molding machine is the core equipment of the molded plastic pallet moulding production line. It adopts high-pressure one-time compression molding technology, and the produced pallets are standard in size and low in cost. At the same time, the source of raw materials is wide, and all kinds of discarded plastics can be used. It is a popular environmentally-friendly new product in the market. The mold is the main component of the plastic pallet molding machine. If you want to produce different types of plastic pallets, you can change the mold.

Production process of plastic pallet production line

The entire production process of plastic pallets is not complicated. The first step is to select raw materials. The raw materials can be PS, PP, LDPE, PVC, HDPE, PET, etc., and most waste plastics. The raw materials plasticized by the plastic extruder enter the storage system, and then through the quantitative feeding device, the raw materials are supplied to the mold according to the required products. The plastic pallet press pressurizes the weighed material and then cools it for a few minutes to form a plastic pallet.

Features and advantages of plastic pallet production line

- Our machine adopts compression molding technology, and the pressure provided by the hydraulic system is used to make the plastic pallet formed in the mold, which can greatly reduce the processing cost.

- All kinds of waste plastics can be used as raw materials, which can recycle resources well. And the process flow of the production line is simpler and easy to operate.

- In the process of production and processing, manual operation is not required. Setting the parameters on the control panel of the plastic production line can realize long-term, stable and efficient automatic control.

About Us

Our company is a professional pallet machinery manufacturer. This production line is developed by our company’s technical department based on years of practice. The entire molded pallet production line has good stability, high production efficiency, low energy consumption, long machine life cycle, stable production, and high load-bearing capacity of the plastic pallets made. If you need a good waste plastic recycling program, welcome to contact us.